Monolithic wood construction

in its purest form.

The VillaVOON team had no lesser ambitions when developing the patented wooden construction system.

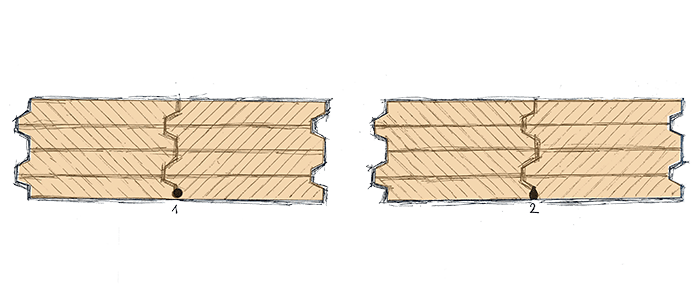

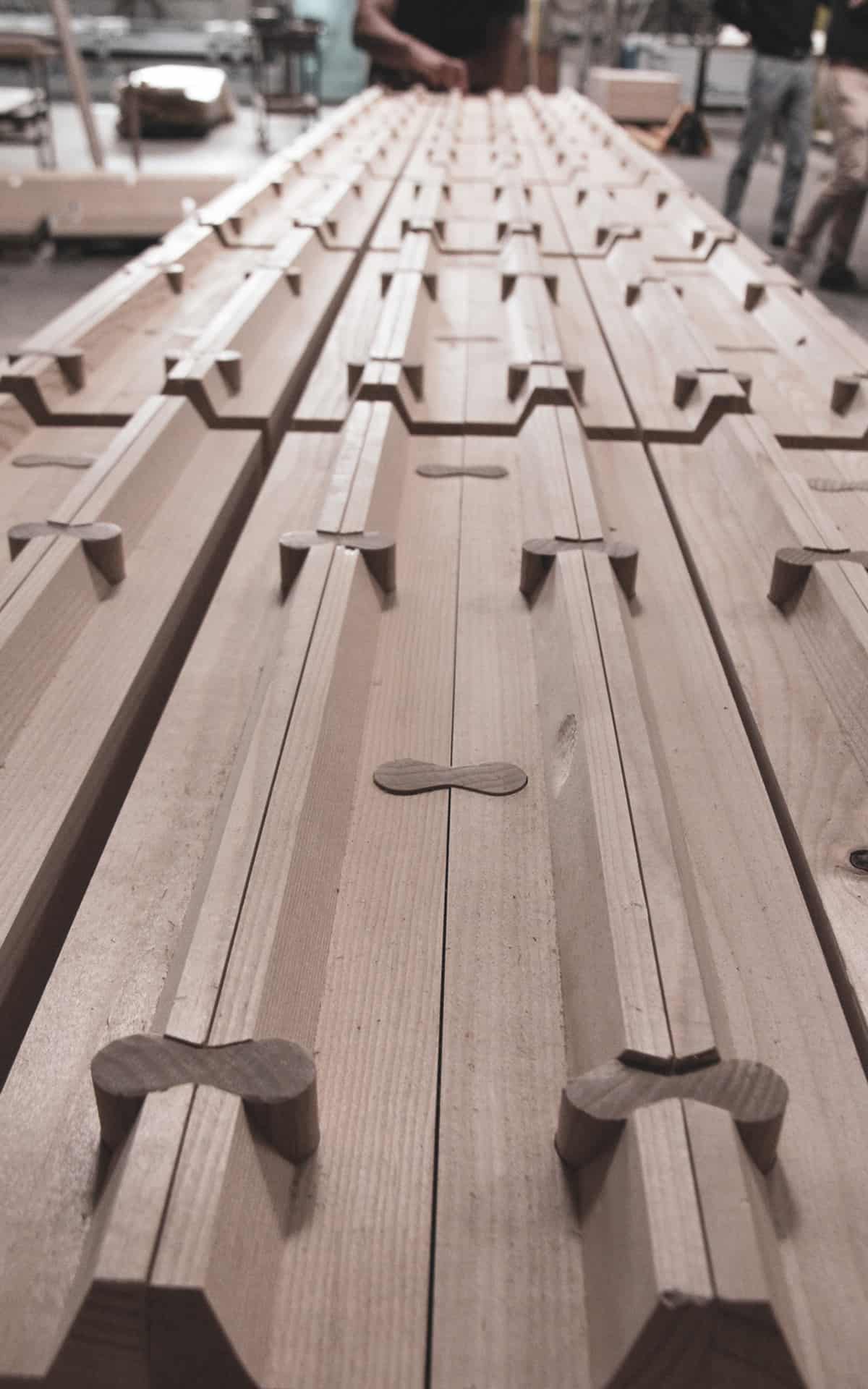

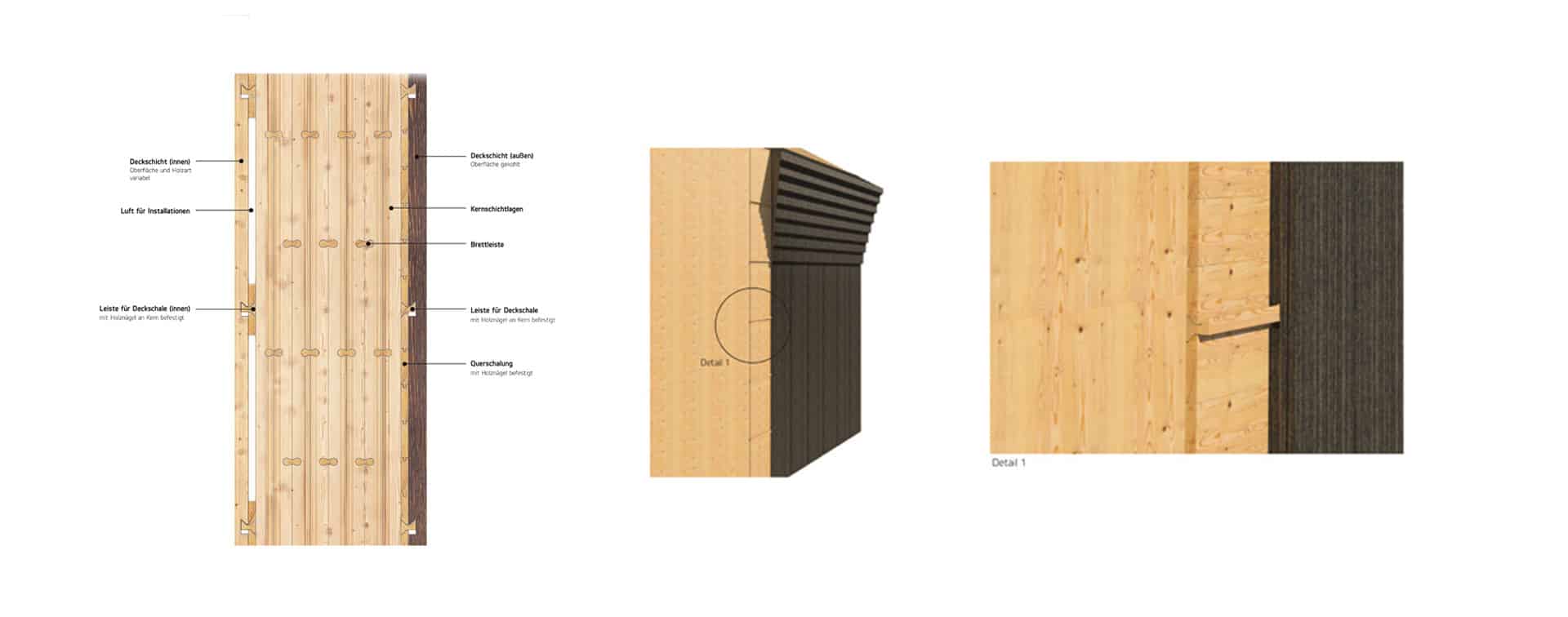

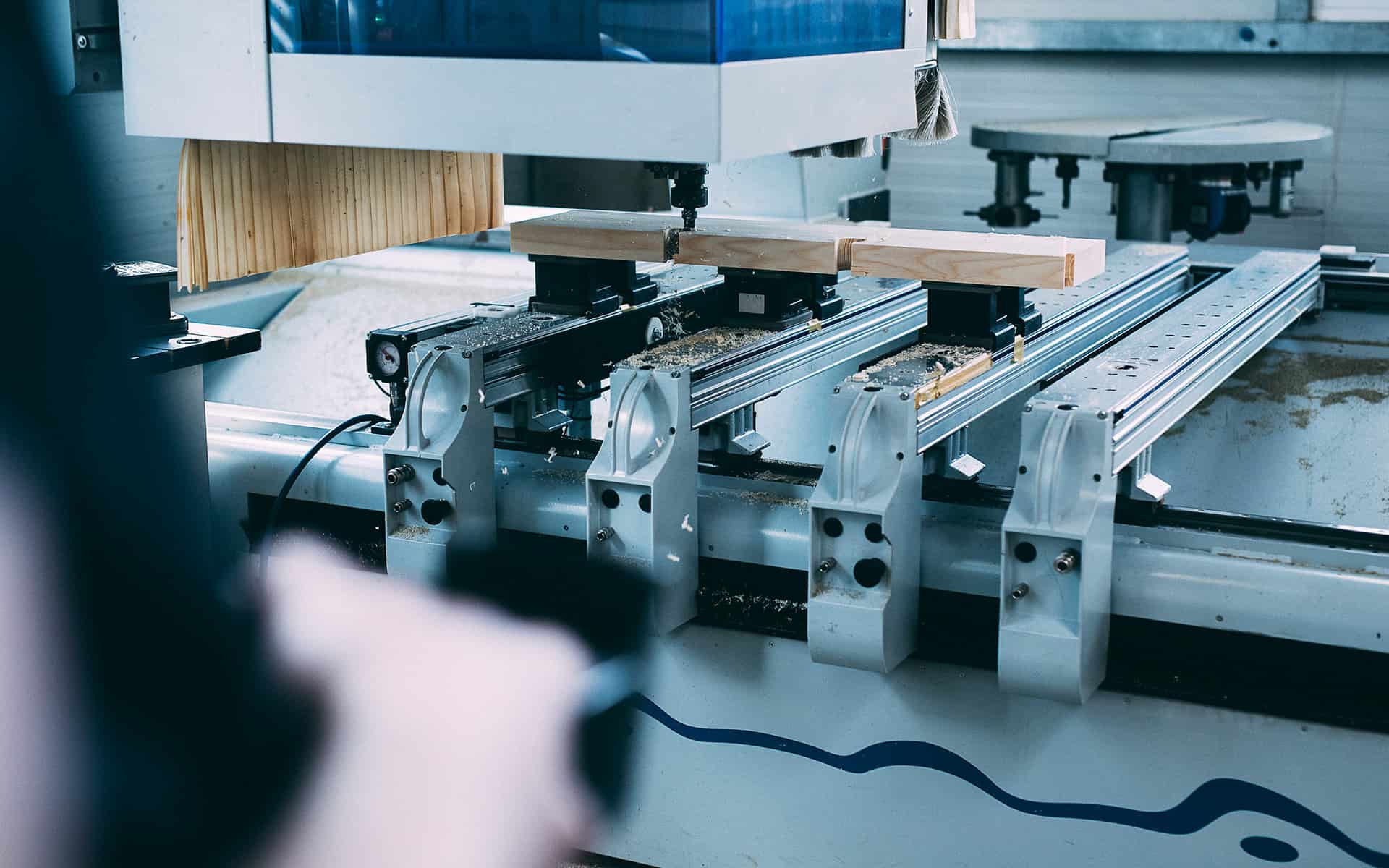

The basic element of the construction system is a wooden post made of spruce, which measures 20 by 5 centimeters in cross-section. After appropriate processing with a CNC milling machine, the posts are assembled into a beam with connecting profile strips made of ash wood. In the next production step, the beams are finally connected to form the frame.

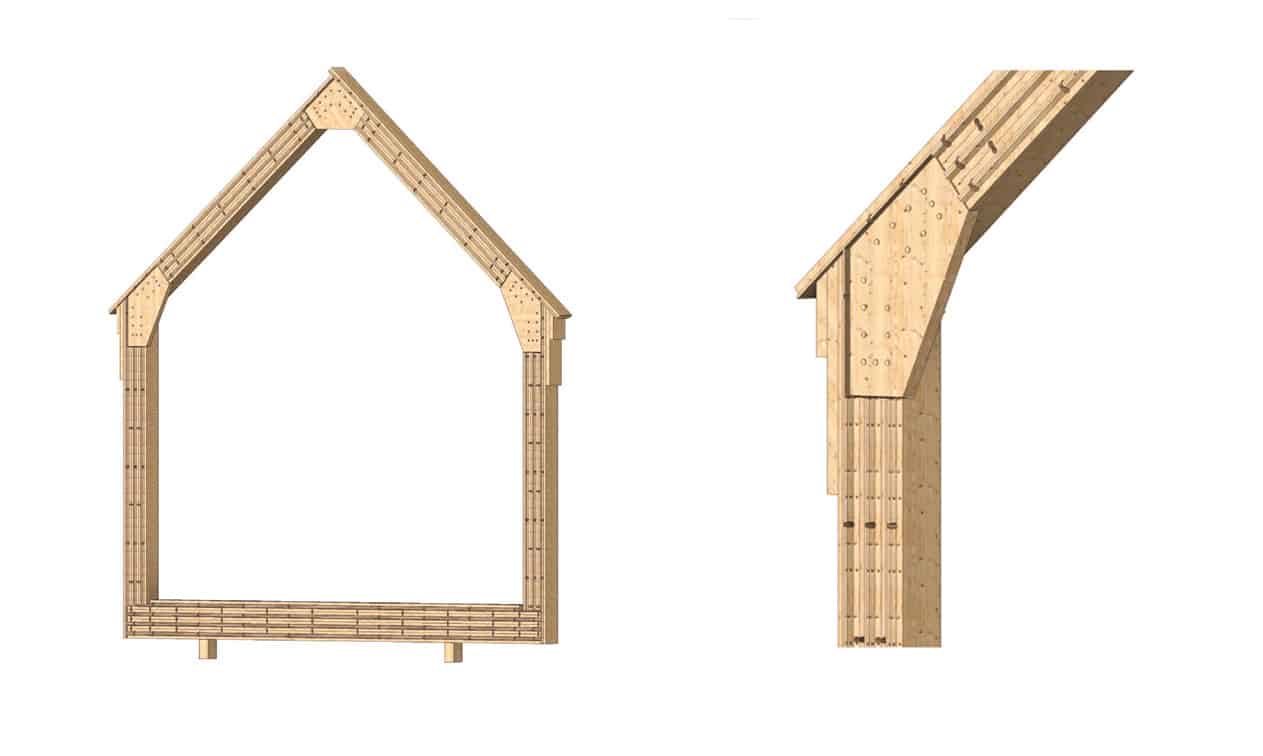

Different shapes and different angles can be produced in this way; only the structural wood protection, i.e. the draining of the water and the drying out of the material, must be guaranteed.

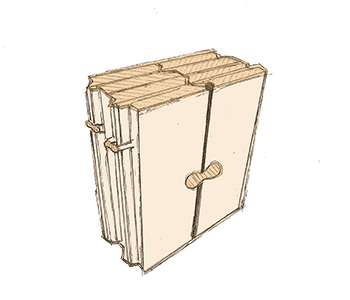

The final step on the way to VillaVOON? One frame after the other is joined together and simply connected to a larger profile made of ash wood. Centuries-old tradition meets modern CNC technology.

Strung together, the frames form the „pure“ villa. The result is a monolithic and diffusible wood system, completely free of adhesives or artificial fasteners. This frame construction method is based on traditional shipbuilding, from which the technique of „caulking“ (sealing with hemp) is adopted. And it is precisely this construction technique that makes the villa not only a unique architectural masterpiece, but also the most natural home of our time..

The foundation consists of concrete piles that lift the VillaVoon from the ground. The distance protects the wood from soil moisture and evokes the traditional base zone of farmhouses.

A VillaVOON is not just built! No, it is composed! Like notes, the panels are lined up on site from left to right or vice versa and connected with wooden materials. Wood is the building material that determines the construction rules, as neither adhesive nor metal parts are used in the construction. For that reason, the VillaVoon system can be used for one to two stories, although there are very few limits to the length and shape of a villa.